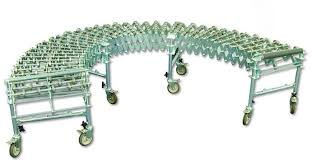

Flexible Conveyors

A flexible gravity conveyor is a versatile and efficient material handling solution designed for temporary or permanent use in various industrial applications. These conveyors are known for their ability to expand, contract, and bend, making them ideal for dynamic and changing work environments. Here’s a comprehensive overview of flexible gravity conveyors, including their components, working principles, types, applications, and benefits:

Key Features of Flexible Gravity Conveyors

Flexibility: Can be easily expanded, contracted, and curved to fit different spaces and configurations.

Portability: Equipped with casters or wheels, allowing for easy movement and repositioning.

No Power Requirement: Operates using gravity, eliminating the need for a power source and reducing energy costs.

Ease of Use: Simple to set up, use, and adjust, making them suitable for various temporary and permanent applications.

Adjustable Height: Many models feature adjustable legs, enabling users to change the conveyor height to match the specific needs of their operation.

Components of Flexible Gravity Conveyors

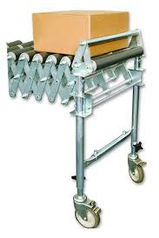

Rollers or Skate Wheels: The conveying surface, typically made of steel, aluminum, or plastic. Rollers or skate wheels allow items to move smoothly along the conveyor.

Frame: The structure that supports the rollers or wheels, often made of steel or aluminum for durability and lightweight.

Leg Supports: Adjustable legs that provide stability and allow for height adjustment.

Casters/Wheels: Attached to the legs, providing mobility and ease of repositioning.

Connecting Hooks or Links: Used to connect multiple conveyor sections, enabling the creation of longer conveyor lines or complex configurations.

Working Principles

Products are placed on the rollers or skate wheels and move along the conveyor path using gravity.

The conveyor can be adjusted to create a slight decline, facilitating the movement of items without the need for external power.

The flexible design allows the conveyor to be shaped to fit different workspaces, making it adaptable to various environments and applications.

Types of Flexible Gravity Conveyors

Flexible Roller Conveyor: Features a series of rollers that support and move the products. Suitable for handling various sizes and weights of items.

Flexible Skate Wheel Conveyor: Uses skate wheels instead of rollers, offering greater flexibility and lighter weight. Ideal for lighter loads and packages.

Applications of Flexible Gravity Conveyors

Loading and Unloading: Commonly used at loading docks and shipping/receiving areas for efficient loading and unloading of trucks and containers.

Order Picking: Utilized in warehouses and distribution centers to facilitate order picking and packing processes.

Assembly Lines: Provides temporary or adaptable conveyor solutions for assembly line operations in manufacturing facilities.

Retail and E-commerce: Used for sorting and moving products in retail distribution centers and e-commerce fulfillment operations.

Temporary Material Handling: Ideal for temporary setups, such as trade shows, events, or construction sites where flexible material handling is needed.

Benefits of Flexible Gravity Conveyors

Versatility: Can be easily adapted to various applications, making them a versatile solution for dynamic work environments.

Cost-Effective: Operates without power, reducing energy costs and maintenance expenses associated with powered conveyors.

Space Efficiency: Expands and contracts as needed, allowing for efficient use of available space and easy storage when not in use.

Improved Productivity: Facilitates smooth and efficient movement of products, enhancing productivity and reducing manual handling.

Portability: Easy to move and reposition, making them ideal for temporary or changing setups.

Flexible gravity conveyors are a practical and efficient solution for various material handling needs, offering versatility, portability, and cost-effectiveness. Their ability to adapt to different spaces and configurations makes them invaluable in dynamic work environments, such as warehouses, distribution centers, manufacturing plants, and more. By integrating flexible gravity conveyors into their operations, businesses can improve efficiency, reduce costs, and enhance overall productivity.