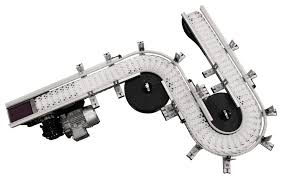

FlexMove Conveyor

FlexMove conveyors, part of the Dorner family of conveyor systems, are designed to provide a flexible, modular solution for various industrial applications. These conveyors are particularly well-suited for automation and manufacturing processes where flexibility, efficiency, and precise product handling are essential. Here’s a detailed overview of FlexMove conveyors, including their features, components, working principles, types, applications, and benefits:

Key Features of FlexMove Conveyors

Modular Design: Components and modules can be easily assembled, reconfigured, and expanded to meet changing needs.

Flexibility: Capable of accommodating curves, inclines, and declines, making them adaptable to complex layouts.

High Efficiency: Designed for smooth and reliable operation, minimizing downtime and maintenance.

Variety of Chain Types: Offers different chain types and materials to handle various products, including delicate items.

Integrated Accessories: Supports a wide range of accessories, such as guide rails, transfers, and sensors, to enhance functionality.

Components of FlexMove Conveyors

Conveyor Chains: Available in various materials and styles, including low-friction, antistatic, and high-friction chains to suit different applications.

Drive Units: Provide the necessary power to move the conveyor chain and can be configured for various speeds and load requirements.

Conveyor Frames: Constructed from aluminum offering durability and stability.

Guide Rails: Adjustable rails that keep products on the conveyor path and can be configured to handle different product sizes.

Support Stands: Adjustable legs or stands that provide stability and allow for height adjustment.

Accessories: Includes transfers, stops, locators, sensors, and other components to customize the conveyor system for specific needs.

Working Principles

Products are placed on the conveyor chain, which moves them along the conveyor path.

The drive unit powers the chain, and the conveyor can be configured to move products through curves, inclines, and declines.

Guide rails and other accessories ensure products remain on the conveyor and are positioned correctly for subsequent processes.

Types of FlexMove Conveyors

Standard FlexMove Conveyor: A versatile option for general material handling applications, capable of handling curves and inclines.

Flexible Chain Conveyor: Specifically designed for applications requiring tight turns and complex layouts, often used in packaging and assembly lines.

Sanitary FlexMove Conveyor: Made with stainless steel components and designed for easy cleaning, suitable for food, beverage, and pharmaceutical industries.

Heavy-Duty FlexMove Conveyor: Built to handle heavier loads with reinforced frames and chains.

Applications of FlexMove Conveyors

Automation and Robotics: Integrates seamlessly with automated systems and robotic arms for precise product handling.

Manufacturing: Used for transporting parts and products between different stages of production.

Packaging: Ideal for moving products through packaging lines, including filling, capping, labeling, and boxing.

Food and Beverage: Handles packaged and unpackaged food items in processing and packaging facilities.

Pharmaceuticals: Ensures precise and hygienic handling of medical products and pharmaceuticals.

Electronics: Suitable for moving delicate electronic components through assembly and testing processes.

Benefits of FlexMove Conveyors

Versatility: Can be customized and reconfigured to meet a wide range of applications and layout requirements.

Space Efficiency: The ability to handle curves and inclines allows for optimal use of available space.

Scalability: Modular design makes it easy to expand or modify the system as operational needs change.

Enhanced Productivity: Smooth and reliable operation minimizes downtime, improving overall efficiency.

Low Maintenance: High-quality components and design reduce the need for frequent maintenance and repairs.

Improved Safety: Integrated safety features and accessories help protect workers and products.

FlexMove conveyors offer a flexible, efficient, and reliable solution for various industrial applications, from manufacturing and packaging to food processing and pharmaceuticals. Their modular design, adaptability to complex layouts, and range of available accessories make them an ideal choice for businesses looking to optimize their material handling processes. By integrating FlexMove conveyors into their operations, companies can enhance productivity, improve space utilization, and ensure precise product handling.